BAERI’s Pardhasaradhi Teluguntla (Pardha) (first author) and his co-authors have received the first place 2026…

Science Backstage: The Earth Science Project Office

By Erin Bregman

Every Tuesday morning, members of the Earth Science Project Office gather around a conference room table at the NASA Ames Research Center in Silicon Valley, California, to problem solve and talk about upcoming mission plans. The 20-person team (call them ESPO) is a diverse group that has been working for over 30 years to master the art of planning and supporting large-scale, multi-agency, airborne Earth science research campaigns. If flying scientific instruments through the atmosphere were a Broadway show, ESPO would be the production managers and crew.

I sat down with Quincy Allison, who has been a member of the ESPO team since 1992, in a small window-lined room at Ames. Though he specializes in shipping and logistics, Quincy has done just about every job with ESPO you can do. His range of experience includes driving forklifts, shipping hazmats, installing radars in foreign countries, and coordinating airlifts. “What,” I ask, “is the most important thing for me to understand about your work?”

“Um,” Quincy thinks for a moment. “We’re saving the planet.”

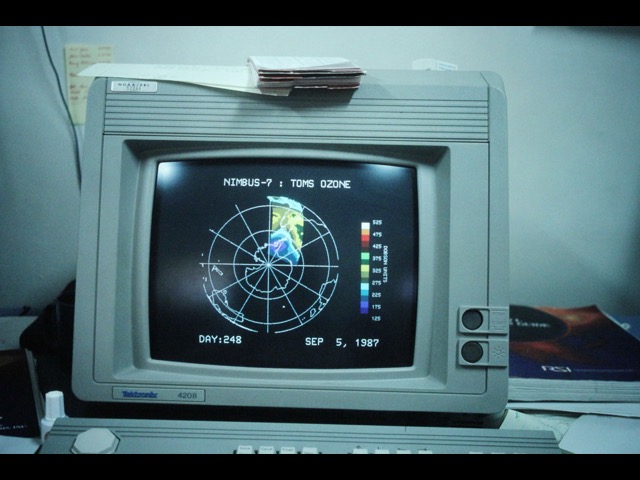

It’s a bold claim, but the team has the work history to back it up. ESPO’s beginnings trace back to the late 1980s. It was a pivotal time for atmospheric research—the existence of the Antarctic ozone hole had been discovered, and human-made chlorofluorocarbons (CFCs) were a likely culprit. There was not yet conclusive evidence CFCs were to blame, but the ozone hole was so unambiguously dangerous that world leaders didn’t wait for conclusive evidence to begin working on a solution. In late 1987, while negotiators from around the world were gathering to hash out the Montreal Protocol, a global agreement to begin the phase-down of CFCs, 150 researchers traveled to Punta Arenas, Chile, for NASA’s Airborne Antarctic Ozone Experiment (AAOE) mission. NASA Ames’s Estelle Condon was the mission’s project manager. For six weeks, the AAOE team flew two aircraft loaded with scientific instruments into and below the ozone hole to collect data about the chemistry at work there. Condon and her small team were responsible for all of the behind-the-scenes work that paved the way for the mission’s success.

Team members David Fahey, Estelle Condon, and Jim Margitan in a hangar in Punta Arenas, Chile, during NASA’s Airborne Antarctic Ozone Experiment (AAOE) in 1987. Image: NOAA/R. Winkler.

In a special edition of the Comptes Rendus Geoscience journal celebrating the 30th anniversary of the Montreal Protocol, NASA’s Michael J. Kuryl recounts the impact of those research flights. The data collected during AAOE, he writes, “became known as the ‘smoking gun’ that identified the chemistry responsible for the Antarctic Ozone Hole. There was now conclusive evidence for the ozone-destroying role of active chlorine from CFCs.”

“It’s kind of hard to get a sense of the international attention we got from that mission,” says Steve Hipskind, who was responsible for providing satellite cloud imagery to the AAOE forecast team. “It was certainly one of the biggest, if not the biggest, science stories of the year.” Though the mission results were not released until two weeks after the Montreal Protocol was signed, AAOE data cemented the case for the complete global phase-out of CFCs, which was adopted in a 1990 amendment.

Because AAOE had been such a success, Condon and her team continued to manage NASA’s international airborne campaigns, including a series of Northern Hemisphere ozone studies out of Norway, Alaska, and Maine. Since then, the team, now called ESPO, has managed over 65 different projects in dozens of countries, on every continent. While no two research campaigns they support are exactly the same, many have similar ingredients: A lot of people, big budgets, limited time, and international locations. It’s not uncommon for ESPO to work on campaigns that involve 300 researchers, span five years, cost $30 million, and use multiple aircraft.

Total Ozone Mapping Spectrometer (TOMS) ozone on a monitor during AAOE in Punta Arenas. Image: NOAA/D. Murphy.

With so many variables, there are plenty of chances for things to go wrong. If you’re a researcher, the nightmare scenario is that when your month of flight days finally arrives, something prevents you from collecting the data you’re there to get—you go home having wasted precious time and money, unable to advance the science.

You could run out of an essential supply, like dry ice to cool sensors, or canisters of specialty gases to calibrate instruments. Any time or energy lost to missed planes, lost passports, spotty internet, or not remembering to bring that one tool you’ll need to fix what breaks, is research time you’ll never get back.

If you’re lucky, you have ESPO. And, long before any planes take off into the air, the team is hard at work making sure none of those nightmares happen.

Not all of ESPO’s projects involve international trips. Their simplest projects are contained within the United States, in one or two locations, and involve instruments and researchers they’ve worked with before. Not too many surprises. Relatively easy.

One such NOAA-led project kicked off in the summer of 2023. Called AEROMMA for short, its full title is Atmospheric Emissions and Reactions Observed from Megacities to Marine Areas. By ESPO standards, it’s not a complex project—it involves about 200 researchers, 33 instruments, and 19 science flights out of both Palmdale, California, and Dayton, Ohio.

AEROMMA’s goal is to learn more about what happens when air pollution from cities meets and mixes with air over the ocean. These interactions impact which compounds end up in the atmosphere, which in turn affects both local air quality and Earth’s overall climate. In North American cities, air pollution is different than it used to be. For decades, fossil fuel–burning transportation was the largest source of volatile organic compound (VOC) emissions in the atmosphere. But regulations have been so effective at curbing vehicle pollution that, in many cities, transportation may no longer be the biggest source of urban air pollution. Recent studies show that VOC emissions from volatile chemical products (VCPs), which include consumer products like shampoo, cleaners, paints, adhesives, and insecticides, could now be responsible for half of all urban VOCs.

The dozens of specific science questions AEROMMA researchers are working to answer can be broken down into two main buckets:

One: What’s the chemistry that’s happening between particles in the air over the ocean? A better understanding of this can help improve global climate models.

Two: What types of VCPs can be detected over big cities, and how much? A clearer understanding of this can lead to better air-quality management.

AEROMMA researchers spent the summer collecting airborne data by flying over the ocean and several big North American cities, including New York, Toronto, Los Angeles, and Chicago. I joined a few ESPO team members in Palmdale, California, at the very start of this campaign to see for myself what ESPO’s day-to-day role in a project like this looks like.

It’s 7:30 a.m. when I head out of my Palmdale hotel room to meet ESPO’s director, Marilyn Vasques. She’s perched on one of two oversized wingback chairs in front of the hotel lobby’s TV, remote in hand, tuned in to NBC. Her sunglasses rest on top of a NASA ESPO baseball cap, a NASA badge on a blue lanyard is slung around her neck, and as the morning news kicks off, Marilyn and the hotel’s breakfast attendant exchange a warm morning greeting. ESPO works from Palmdale so often that the two women have known each other for years.

Marilyn shares her excitement—ESPO’s work is being featured on the news this morning! When the spot starts, Marilyn leans forward, touches up the volume with the remote control, takes a quick glance around to make sure the noise isn’t bothering anyone, and turns it up a hair more.

The spot lasts just shy of four minutes. The reporter boards the plane, chats with the researchers, checks in with the pilots, and introduces the concept of imaging the surface of the ocean as a way to see how the ocean’s currents are impacting climate change. One of the three anchors—of one of the most-watched morning news shows in the country—wraps up the segment by saying, “If Roker were here, he’d have one word … ‘Science!’” And everybody chuckles.

Marilyn shrugs. “Oh well,” she turns the volume back down, “Erin and Sommer didn’t get their two minutes of fame.” An earlier draft of the segment had featured ESPO’s Erin Czech and Sommer Nicholas pointing at something. It had been cut, which meant no trace of ESPO.

Marilyn places the remote back on the table, and we walk out of the hotel to our cars, and we drive nine minutes down the road to work.

It’s a four-mile drive down one straight, flat road to get from the hotel to the NASA facility where we’re heading—Armstrong Flight Research Center’s Building 703—and the convenience of the hotel’s location is one of a long list of things Marilyn and her team pre-solved a long time ago. It’s an early May morning, clear and cool, and there’s still plenty of snow visible on the distant San Gabriel Mountains as I drive past Joshua trees, past two side-by-side museums full of historic air force planes, and turn left into the long approach to the hangar.

The view leaving Building 703 at NASA’s Armstrong Flight Research Center in Palmdale, California. Image: E. Bregman.

The hangars here would look huge, except that the landscape they sit in is even huger. On the parking lot side of a barbed-wire-topped fence is the NASA badging office. I was here yesterday to share my two forms of ID, fingerprints, and stand for a picture. Today, Marilyn’s colleague Jhony Zavaleta, ESPO’s deputy director, greets me by name. His straight dark hair is cut short, and he’s in a blue polo shirt, hiking pants, and sturdy shoes.

While my NASA badge prints, Jhony and Marilyn check in about yesterday until his phone rings. It’s ESPO’s event and project coordinator, Daisy Gonzalez. “Do we have room for all of the dry ice?” Jhony asks her, as Marilyn and I walk out the door, through the gate, and into the lab.

The lab is a long room lit by fluorescent lights, and features the white and gray speckled ceiling tiles of elementary school classrooms and doctor’s offices. There are 23 researchers here today from about a dozen different teams. More groups will rotate through all month. This morning, one researcher stands working at a metal workbench with a mini screwdriver and a headlamp. Another strips wire with pliers. Nearly everyone wears clothes you could hike in—T-shirts and shorts or athletic pants, long-sleeved light-weight shirts, walking shoes.

Halfway down the room are two end-to-end plastic folding tables and a whiteboard on wheels. This is where the ESPO team will work for the next month.

It’s the first day of integration for AEROMMA, which means teams of atmospheric chemistry scientists are just getting to work opening crates and boxes to assemble their instruments, which will soon get installed on NASA’s DC-8, a four-engine narrow-bodied jetliner that’s outfitted to be the world’s largest flying chemistry laboratory.

The DC-8 is big. At 150 ft. long, with a nearly150 ft. wingspan, it’s a workhorse of an airborne science machine. When full, it can carry up to 30,000 lbs. of scientific instruments, plus 45 researchers and crew. It’s not a new plane—built in 1969 and acquired by NASA in the mid-1980s, this DC-8 is one of the last three still flying in the world. AEROMMA is slated to be one of its final outings, and NASA has recently purchased a much larger plane, a 777, to retrofit and replace it with. This Palmdale hangar is the DC-8’s home, which means no matter where ESPO’s projects take them, if the DC-8 is involved, they begin in Palmdale.

As Marilyn walks me down the hangar, she stops to check in with nearly everyone we pass, mostly members of the ground crew whose home base is Palmdale, and who travel with the airplane wherever it goes—not folks who are directly on her team, but close collaborators. There’s ease in each encounter. Everyone seems genuinely happy to see her. The conversations are a mix of the personal and the practical: How are you doing? How are you feeling about the new 777? Will you move with it? Stay here?

NASA’s DC-8 airplane in Palmdale. Image: Jane Berg.

The 777 is too big for this hangar, which means crew will have to choose whether they’ll relocate to wherever NASA decides to house the new plane, or find different work. It’s a sensitive topic, but Marilyn doesn’t shy away from it. “It’s important to talk about the elephant in the room,” she says as we finish up a third hangar conversation and approach the plane.

Inside, the DC-8 is empty—no seats, no people, no instruments.

NASA made extensive modifications to the plane to transform it from a passenger plane into a modular lab. All of the seats were removed, and many of the windows were replaced with removable ports, which allows researchers to have instrument apparatuses sticking out into the air during science flights.

Over the course of the next month, this plane will fill up. Thirty-three instruments, each one custom built, will be assembled, each in a metal crate, lifted into the cabin, wheeled into place, and bolted down. Right now, all that’s here is a map detailing which instruments are about to go where.

Interior of the empty DC-8 at the start of integration for Atmospheric Emissions and Reactions Observed from Megacities to Marine Areas (AEROMMA) in Palmdale, California. Image: E. Bregman.

After visiting the DC-8, Marilyn and I walk to the other end of the hangar and stop in front of a set of doors. “Which door is it?” As she finishes the question, one of the doors magically rolls up, and we walk through it back into the lab, past a “lasers in use” sign, out another door, and up a long flight of metal stairs. “I’ve been in so many hangars, I’m getting my hangars confused,” she explains as we walk down a hall and into an office that’s been split into cubicles for about 20 people. It’s a maze of blank walls, empty desks, and one folding chair.

Marilyn takes a quick walk through the room before returning to where I stand, offering me the only chair, and taking a seat on the desk herself. “When you go back down, tell Jhony about the chairs,” she says. “We must be using the space before he thought it would be used. Not sure when the PIs will start using it but not having chairs isn’t ESPO’s style.”ESPO’s style, from what I can tell, is to solve problems you didn’t know you’ll have so that you never actually have them. Marilyn calls it doing whatever is needed so that researchers are able to focus on their research. As one of her colleagues Sommer Nicholas once explained to me, they’re like roadies for research scientists. Before ESPO, Sommer spent time as a production manager for the Vans Warped Tour, a summer rock concert that was the largest traveling music festival in the United States. And like the best roadies, ESPO’s work, when it’s at its best, is invisible. “But when a researcher’s in trouble,” adds Marilyn, “they know who to call.”

Jhony Zavaleta, of the Earth Science Project Office (ESPO), at work during AEROMMA. Image: NASA ESPO/Monica Vazquez Gonzalez.

ESPO’s work for a given project starts years before anyone walks into a hangar. They’re involved at the beginning of the beginning, when a project is little more than a proposal and a budget. Though most of their research campaigns are NASA-funded and led, they aren’t exclusively so—some are led by NOAA with NASA as a partner, and others involve partnering with foreign government agencies, including the Japan Aerospace Exploration Agency, South Korea’s National Institute of Environmental Research, and Costa Rica’s Centro National de Alta Tecnologia.

Some of the biggest NASA projects ESPO manages are Earth Ventures missions. These are highly competitive NASA Earth science missions that are relatively low-cost, though low-cost for the suborbital category (i.e., airborne flights) means a $30 million cap per project. In the early days of Earth Ventures, NASA research groups would seek out ESPO during proposal writing, both to write them in as project management and to get their help with the proposal itself. After several rounds of Earth Venture proposals, it became clear that research groups felt that those who had ESPO on their team had a greater chance of success—so much so that this was taken into consideration when NASA revised the Earth Ventures process. To even the playing field, it was agreed that project-management teams would not be part of the proposals. Instead, groups would select their project-management teams after proposals were awarded. ESPO used to manage one or two big projects per year. Now they do that plus three Earth Ventures missions.

To give me the full scope of what ESPO does, Marilyn pulls up a PowerPoint presentation on her computer and walks me through it. There’s information about where ESPO fits into the greater NASA hierarchy. There’s information about how the team is built as a combination of NASA civil servants and Bay Area Environmental Research Institute (BAERI) contractors. Each position type has its advantages and limitations, and ESPO would never be able to function the way it does, Marilyn tells me, without the team being a mix of both. “But I try to make it like a family,” she says, “Whatever I can do for one, I do for the other.”

The split structure of the group is highly practical. A lot of ESPO’s work involves navigating government systems, and sometimes it’s helpful to be a government employee while doing that, and sometimes it’s more helpful to not be. Civil servants, as employees of the federal government, are able to spend government funds and talk to embassies—both of which are essential for ESPO’s work. A non-government employee can’t do either of those things, which means at least some team members on each project must be civil servants.

On the other hand, international travel when you’re a government employee gets complicated fast. And at times, especially with last-minute travel, it might not be possible at all. A BAERI employee can simply go to the airport, buy a ticket, and board a plane to wherever they need to go. It can take 60 days to get international travel permissions for a civil servant. “In an emergency,” says Marilyn, “I can ask a BAERI person to get on the next plane.” Emergencies happen. This isn’t a hypothetical. It’s an ask Marilyn’s had to make before, and fortunately, when last-minute travel needs arise, she’s always had a team that wasn’t only government employees.

Marilyn is a NASA civil servant. So is Jhony. Daisy, one of the newest members of the team, is a BAERI employee. And while those in civil servant positions sometimes start as BAERI employees and then move into a civil servant position when one opens up, it’s not always a marker of seniority, or the desired path. Some people begin as civil servants. And Quincy, who’s been with ESPO for 30 years, is one of BAERI’s longest-term employees.

The ESPO team has grown to meet its expanding workload, but not always quickly enough. When there’s too much work for the size of the group, Marilyn will step into any role that needs to be filled. In one particularly busy year, she racked up 133 days of travel. When management at NASA headquarters got wind of this, they told her to hire more people and provided the needed funds to grow the team.

But having more money doesn’t necessarily mean having the right people, when finding the right person is about more than what’s on their resume. Before joining ESPO, Quincy was a carpenter. Sommer was a rock-concert roadie. Daisy planned events for the mortgage industry. Jhony was an engineer with Honeybee Robotics and worked on a Mars drill and analog missions in Spain. Marilyn worked as a zoologist on the shuttle program. Others on the team are former military or worked in the shipping industry or studied library science. When someone checks all the right boxes, it’s not just because they’re organized (though they’re impeccably organized), or proactively service-oriented (that’s a must), but it’s because they’re also someone everyone on the team would want to travel with, then sit next to in close quarters at a plastic table, in a foreign country, for 12-plus hours a day, for a month.

AEROMMA is Daisy’s second field campaign, and in the time I spend with ESPO, Jhony is consistent about finding opportunities for her to learn new parts of the job. Sometimes that looks like talking her through how a spreadsheet is organized. Other times it’s figuring out what to include in the daily schedule before she posts it, along with the photo of the day, to the AEROMMA website and WhatsApp thread.

One afternoon, it looks like this: Two researchers approach the ESPO table with a problem. One of their new gas canisters is empty. Jhony asks Daisy to check with their gas vendor about the turnaround time for a new one and steps away to help them move the empty canister.

Daisy calls the local vendor, but he seems confused. Because running out of gases is a big problem for researchers, Daisy and Jhony decide to go talk to the vendor in person. Jhony invites me along, I volunteer to drive, and we go.

It’s a 20-minute drive north through the desert to the gas vendor in Lancaster. We walk from the parking lot through a barbed-wire-topped gate into a yard lined with gas canisters in crates. Jhony stops to point out the safety caps that help prevent canisters from getting accidentally opened. Not all countries use those, he tells Daisy, so be extra careful if you’re ever moving gases in other countries—check for caps.

ESPO’s Jhony Zavaleta and Daisy Gonzalez visit a gas vendor during AEROMMA. Image: E. Bregman.

Inside, the small building looks like a ghost town hardware store—dusty, but stocked.

An employee stands behind the counter. We’ll call him Andy. He’s in a dark polo shirt over a light-blue long sleeve. His jeans are dirty, his beard is white, and his gray hair is pulled back into a ponytail.

Jhony hangs back, and Daisy introduces herself and the order-updating purpose of her visit. Andy’s mad. “Well none of that’s done! I have to write it up!” He turns and walks away into the office. Jhony leans against the counter to Daisy’s right.

Andy returns with a printed email and a blue BIC pen. Daisy starts reading through the details of their order. Her nitrogen numbers leave him flabbergasted. “They’ll bleed out in the first week! You can’t order that all at once.”

Daisy looks to Jhony for help, and he looks at her list. Jhony clarifies: We’re talking about regular nitrogen.

“Oh,” Andy stops. “I was talking about liquid nitrogen.”

Back and forth, Daisy and Andy read off dates, numbers, and sizes of canisters for each delivery. As they do, Jhony’s double checking it all on his phone. The conversation sounds like code to me, it’s a language Daisy is learning to speak, and it goes something like this:

“Ks is 200?” This is Daisy, clarifying the terminology for canister sizing.

“Yes.” That’s Andy.

“Then seven of the Ks.”

“What about Ts?”

“If Ts is 300, that’s … five.”

“When do you want them delivered?”

“As soon as possible.”

“How about the 200 airs?”

“Six of the 200.”

“This stuff has to be ordered months ahead, this is really screwing everyone up!”

With a calm curiosity, Jhony leans over to look at Daisy’s list, looks up at Andy, and asks, “Weren’t those bottles supposed to arrive on the 22nd anyhow?”

“They didn’t order Ks, they ordered Ts.”

Jhony thinks. He turns to Daisy. “They’re heavier, they’ll be a pain to move. Let’s take a look at the T’s.”

Andy leads us across the shop and up three stairs to a metal platform packed with canisters nearly as tall as I am, or taller.

“Do you want all nine of those?”

“We need twelve,” says Jhony. “Tuesday.”

Andy writes it down. “And this guy ‘Jhony‘ …?”

Jhony smiles. “That’s me.”

Back at Ames, Quincy fills me in on his role with the Palmdale gas order, which had challenges from the start. “They were now calling ultra zero air a specialty gas, which I’ve never run into,” he said. In all his years of logistics, it had been considered a standard gas, which meant an order that had always needed one week of lead time now suddenly required a month. “I just got lucky that I inquired two months early, but then all of a sudden there was a delay in the month getting it, so there were some last minute issues.”

This isn’t a vendor-specific problem. The global specialty-gas industry is still struggling with post-COVID supply chain issues, including worldwide shortages of helium and carbon dioxide. It makes ESPO’s job of ensuring there’s enough of the right gases on-site and on-time an ongoing challenge.

But on the scale of challenges ESPO knows how to navigate, it’s a pretty lightweight one. They also know, from experience, how to:

- Transport very large and very expensive objects (like RVs, or radars) overseas to wherever researchers need to use them.

- Build a new hangar on an air base in South Korea.

- Buy a shipping container’s worth of parts for the DC-8 in Peru and get it back to the US.

- Simultaneously negotiate with the Costa Rican embassy and Office of International and Interagency Relations for a one-day turnaround to import specialty jet fuel.

- Host the Nobel Prize–winning president of Costa Rica; show him around.

- Conduct and lead outreach events at local schools.

- Coordinate researchers and planes and instruments to travel from Palmdale to Alaska to Hawaii to Fiji to New Zealand to Chile to Brazil to the Azores to Greenland to Alaska smoothly enough for world-class science to happen during every leg of the trip.

Quincy’s experience alone spans more than 50 different projects on every continent on Earth. One of the bigger logistical challenges he helped solve was for the 2007 Tropical Composition, Cloud, and Climate Coupling (TC4) field campaign. The main goal of TC4 was to better understand the role that the tropical tropopause layer plays in Earth’s climate and atmospheric chemistry. Sometimes called the “gateway to the stratosphere,” the troposphere is the innermost layer of Earth’s atmosphere and stretches from ground level to about five to nine miles high, depending on where you are on the planet.

The TC4 field campaign wasn’t a simple one. It involved over 600 researchers, who installed more than 70 instruments onto 3 different airplanes for a total of 26 science flights out of Costa Rica’s Juan Santamaría International Airport, just outside of San José. In addition to science flights, the campaign also collected data via two ground-based radars, and an assortment of weather balloons launched from Costa Rica, Panama, and the Galápagos Islands. ESPO’s Costa Rican airport preparations for the campaign included reconstructing an old hangar to house one of the airplanes, and arranging for the loan of another hangar—which was owned by the president of Costa Rica—to house one of the others.

The Tropical Composition, Cloud, and Climate Coupling (TC4) operations site in Las Tablas, Panama, 2007. The NASA S-band Dual Polarimetric Radar (NPOL) is on the left, and the Nittany Atmospheric Trailer & Integrated Validation Experiment (NATIVE) trailer is on the right. In the center, a radiosonde balloon is being prepared for launch. Image: NASA ESPO.

To get the data they were after, the TC4 science team needed one of their two radars installed near the Gulf of Panama. Quincy was part of the team that helped find and prepare a site for the radar, figure out how to get it there, and get it set up.

How, I wanted to know, do you start a project like that? “The science team has deployed this radar in different locations before,” said Quincy, “so you definitely get with them and say, ‘Hey, what are the problems you ran into before? What are your requirements to set this up and keep it running?’ So you start with the list of requirements, and then a lot of it’s winging it.”

The list of requirements in hand, ESPO found a suitable location: a hill in the middle of a cow pasture in Las Tablas, Panama. Once they’d tracked down the Panamanian farmer who owned the land, they met him for tea, and with the help of a translator from the embassy, negotiated a price for renting the land, and got permission to do the needed construction. Quincy had a road built, flattened the top of the hill, and put up cattle fencing. The ESPO team coordinated the radar delivery and the crane-assisted setup. “I want to say the [radar’s] antenna was maybe 30 ft. in diameter,” said Quincy. A radar that size isn’t typically mobile. This one had been modified to be taken apart, shipped by sea in five or six shipping containers, and then re-assembled on-site with the containers as its base. Once it was built, they also had to “get internet in there, generate power, all that type of stuff.” The ESPO team got the radar up and running in less than a month.

Because of his depth of experience in the very specific field of international airborne science campaign logistics, Quincy has become a go-to person for researchers around the country who don’t have ESPO helping them and need to figure out for themselves how to get their equipment to international locations. “I get outside requests all the time—people with other projects, going, ‘Hey, we’re doing a project. I know you’re not supporting it, but how do I get stuff to South Africa? How much is it going to cost me?’ It’s a fairly small community, the science community that we work with. So I’m always trying to help people out” says Quincy.

There are region-specific differences. “Shipping to Southeast Asia is going to have a whole different set of problems compared to shipping to South America,” says Quincy. But there are country-specific quirks too. When shipping to Costa Rica, for example, “you need serial numbers and model numbers and itemized lists.”

There are times when even decades of experience and top-notch advice can’t pre-solve a problem. If a vendor makes a mistake or a research group doesn’t follow ESPO’s instructions, it can result in costly delays or lost data. There are always risks with shipments, and sometimes there’s no fix ESPO can offer.

One time, during the first shipping mission Quincy ever supported, a partner agency didn’t follow ESPO’s tips on how to ship their equipment. For this campaign, which was looking at how a choppy ocean surface affects how much CO2 is transferred from the atmosphere to the ocean, researchers needed to get themselves and their gear to Punta Arenas in Chile, and then onto a ship to Antarctica.

Quincy worked with a local Chilean agent to understand the necessary shipping details and passed that process on to the teams. The NASA equipment got there, but the rest of it, which was the majority of what the researchers needed, got stuck in customs. They hadn’t followed Quincy’s guidelines. The people had all arrived, “the boat’s sitting there, but they can’t leave because their equipment isn’t on it, and it’s costing, you know, $50K a day, or whatever the price tag is,” says Quincy. “We had to jump through a bunch of hoops to get their equipment out of customs.”

With the addition of COVID’s supply chain issues and sea shipping delays, sending equipment around the world has become more and more unpredictable. “We ran into so much trouble with getting stuff to Korea this last summer,” said Quincy. He sent everything three months in advance, and there was one delay after another. “Did anything not make it in time?” I ask. Quincy thinks, shakes his head. “No.” Everything made it.

“To me, what logistics is about is trying to anticipate your next step,” Quincy tells me. “And even if you’re anticipating the wrong step, at least you have some type of plan in place, and you can adjust.”

Back in Palmdale, I’m sitting with Daisy and Jhony at the ESPO table in the lab one afternoon when a researcher stops by to let us know it’s time: their instrument’s about to get loaded onto the plane. Do we want to watch? Daisy and I hustle out the door and down the hangar to the DC-8, where NOAA’s Aerosol Microphysical Properties (AMP) instrument team stands below the plane with their instrument. It’s been assembled and bolted into a large metal rack. The rack rests on a dolly.

The Aerosol Microphysical Properties (AMP) team from NOAA getting ready to install their rack in the DC-8 during AEROMMA. Image: NASA ESPO.

We watch three people on the team push the dollied instrument into the back of what looks like a standard box truck, NASA logo on its cabin. When the instrument’s inside, the whole truck bed lifts up to the level of the plane doors, and the researchers push their instrument from the truck onto the plane, where they then use a long wooden lever with wheels on the bottom to help tip the instrument off its dolly and scoot it into place.

There’s some confusion about the instrument’s exact placement (“Do we center it at 650, or put the front at 650?”), so they decide to wait to bolt it down until tomorrow.

Later, as I’m walking across the hangar with Jhony, he tells me that, living near the San Jose, California airport, he sees planes full of people taking off and landing all the time. It’s so routine, he thinks nothing of it. But this plane? “It’s a different feeling to watch this plane take off.” Inside are all the people he’s been working with for weeks on end. It’s like a family, he says. And then he describes how, whenever this old flying laboratory and its researchers land, everyone who hasn’t flown that day spontaneously heads out to the runway to greet them.

In the months after my visit to Palmdale, the last of AEROMMA’s 19 science flights have landed, and Quincy, Jhony, Daisy, Marilyn, and the rest of the ESPO team have scattered around the world to support a whole host of other projects:

They’ve been to Asia doing site visits for a 2024 air-quality study that will have flights out of the Philippines, South Korea, Malaysia, and Thailand.

They’ve been to Pituffik, Greenland, for a site survey before a summer 2024 research campaign about Arctic sea ice melt.

They’ve been to northern Nevada to set up three ground sites for a study of the Osiris REX re-entry, which brought NASA’s first asteroid samples back to Earth.

They’ve been to Utah and Arizona to support a controlled burn as part of NASA’s latest wildfire research.

And they’ve been to South Africa for a biodiversity survey of the Greater Cape Floristic Region, where 30 research flights wrapped up in November 2023.

By late September, the AEROMMA WhatsApp groups have gone quiet, but I scroll up through the final week’s posts to check in on how the campaign wrap-up went. On the “AEROMMA Fun & Media” thread, researchers shared snapshots and video clips of various sightings of the DC-8 from the ground (“Everyone likes the DC-8 ♥️”).

On the main AEROMMA thread are early results (“We saw overlying biomass-burning particles, and the sea salt particles brought by the hurricane”), bolded safety reminders (“You must wear a reflective vest when walking from the ramp to the hangar after sunset”), and miscellaneous lost and found (“Has anyone seen a pair of red-handled diagonal wire cutters, labeled AV22?”).

ESPO’s Andrian Liem and Michael Schroeder unloading the AEROMMA science shipment while the remnant of Hurricane Hilary dumps inches of rain. Image: NASA ESPO.

Back on August 21st, the photo of the day is ESPO’s Andrian Liem and Michael Schroeder, bundled up the previous day against the pouring rain from the remnant of Hurricane Hilary, using a forklift to unload a truckload of AEROMMA science equipment that had arrived back in Palmdale from Ohio.

The final message, posted September 6th by Andrian Liem, links to a feedback survey for all AEROMMA participants. There’s a thank you, a deadline for offering feedback, and the link.

“We appreciate your participation,” the post ends, “and look forward to serving you better in the future.”